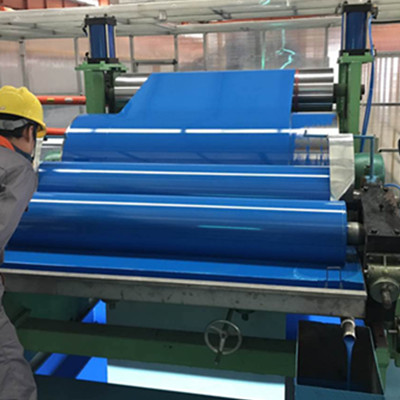

High speed color steel coil production line

Color coated coil normally refers to the product of cold rolled or galvanized steel coil, whose surface is pretreated (degreased, phosphated or passivated), then coated (or rolling printed) a layer of dye and dried up, of whose character can be machined directly. Due to the features of high intensity, high corrosion resistance, easy machining performance and rich color options, etc, it’s broadly applicable to the industries of civil construction, communication, light industries, home appliance, automobile and so on, particularly in civil construction industry, plants, relocatable houses, doors and windows have considerable demands of the plate.

colored steel coil production line

Technical Parameters:

| material | Electric-galvanized coil, hop-dip galvanized coil, cold-rolled coil, hot-dip Al-Zn coil etc |

| Width of steel coil | 500-1750mm |

| Thickness of steel coil | 0.1-1.5mm |

| Outer diameter of steel coil | Maxφ2000mm |

| Inner diameter of steel coil | Φ500mm |

| Process speed | 25-180m/min |

| Thickness of coating | 5-30μm for the single-layer dry film on the front face (regulated as required) |

| 5-20μm for the single-layer dry film on the back face (regulated as required) | |

| Production capacity | 100,000-250,000t/year |

| Energy type | Electric, gas, liquefied petroleum gas, coal gas etc |

GEIT provides one-stop service from general planning, designing, to manufacturing, installing, commissioning and after-sale servicing. Besides, our business also covers single equipment’s designing, manufacturing and installing, as well as electric transmission, control system and spare parts.