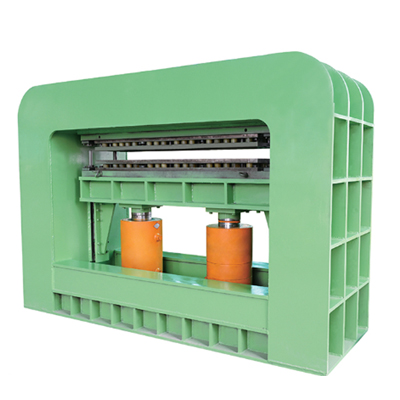

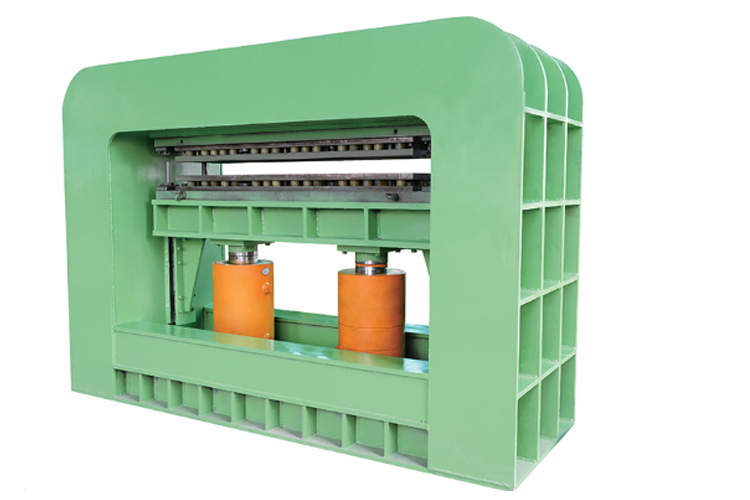

High-efficiency multi-color coating sewing machines

Product Introduction:

The machine is dedicated equipment applicable to the head-tail connection of plates and strips in the production line of coating and galvanizing of steel plate, copper plate, aluminium plate, galvanized plate and various plate strips, and is composed of steel-structure body, mold, synchronization system, guiding device and hydraulic system. It can directly lock and sew the strip tail of the coiled plate and the strip head of the next coil without stopping the machine during the operation of unit. The machine has advantages of simple operation, firm sewing, energy-saving and time-saving etc.. According to the number of sewing rows, the sewing can be divided Into single-row sewing and double-row sewing, and according to the sewing thickness and width, it can be divided into multiple specifications.

Performance of High-efficiency multi-color coating sewing machines:

| Applicable materials | Steel plate, cooper plate, aluminium plate, galvanized plate and various plate strips. |

| Material thickness | ≤3.0mm(aluminium plate≤6.0mm) |

| Materials width | ≤1800mm(aluminium plate≤2100mm) |

| Number of sewing rows | 1-2rows |

| Working pressure | ≤21Mpa |

| Sewing time | ≤10s |