GEIT Electric Equipment Factory

Coating room- color coating line

After leaving the chemical pretreatment section, the steel strip continuous entry the process section for coating. GEIT color coating line adopts double coating and double baking method for the steel coil coating.

Firstly, the steel strips enter into the primer coater for primer coating, the upper and lower heads of primer coater are both double-roller type, the paint is pressed into the paint tray from the paint bucket by pneumatic pump and coated on the strip surface by the staining roller and coating roller. According to different requirement, we can design various coating form to satisfied your need, like “single coating/no coating, double coating/no coating, double coating/single coating, double coating/double coating” to the front/back surfaces of the strip. after primer coating, the strips enter into the curing oven for heating and curing, the temperature in oven is continuous increased. During the solvent evaporation, the strip temperature rise slowly, then when the coating starts to aggregate, the strip temperature rise rapidly so as to complete the whole curing process. afterwards, the steel strip come out from oven and then pass through the cooling device to make the coating be cured.

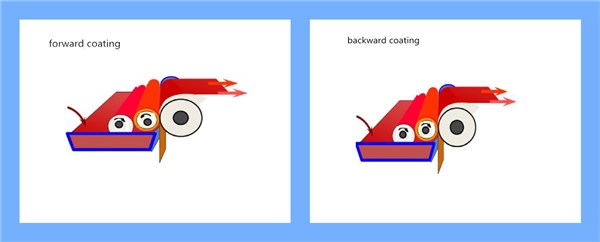

Secondly, the steel strip has to enter into the finish coater for precise coating. the finish coater adopts two roller type. It plays an main role in deciding the performance of steel strip color, thickness and evenness. It can execute the forward or backward coating operation according to specific situations(backward coating method suitable for low viscosity or medium viscosity paint and forward coating method suitable for low viscosity paint, the coating film is thinner). and then, the steel strips also should be sent to the furnace for curing. the curing time is determined by parameters of strip thickness, coating type, coating thickness and curing temperature. the oven temperature is usually controlled within 250℃-350℃. at last, the strip from the curing oven is cooled by air and water to make the coating be cured.

Generally speaking, the strip pass through “primer coating, primer curing, cooling, finish coating, finish curing and cooling” to finish the whole coating process in coating room.